Lean manufacturing is a production process focused primarily on maximizing productivity while simultaneously minimizing waste within a manufacturing operation. Many manufacturers use lean manufacturing principles to eliminate waste, optimize processes, reduce costs, increase profits, and improve quality.

According to the Lean Enterprise Institute (LEI), the leader in lean knowledge and training, the five key principles of lean manufacturing are: identifying product value, mapping the value of each product, creating value flow without interruptions, establishing customer pull value, and pursuing perfection. Our lean manufacturing space experts use these principles to minimize waste and maximize efficiency with the help of superior industrial products, more dependable safety equipment, and better ergonomic solutions.

Our ergonomic workbenches meet any industrial workstation needs, ranging from low-cost standard workbenches to advanced adaptable designs customized for an existing production line. A well-functioning workstation creates the conditions to work effectively, which in turn improves productivity and well-being at work.

These quality workbenches are designed to withstand years of heavy use. Modularity offers agility and lengthens product life cycles. The widest range of accessories on the market gives us the ability to create personalized, ergonomic, and flexible workstations for employees. This ensures safe, easy-to-use, and motivating working conditions all-around.

We’ve selectively partnered with a great storage manufacturing expert, Rousseau, who has developed many different industrial products to meet the standards of the 5S methodology. The aim of this technique is to improve the work environment constantly. Its name comes from the same first letter used to illustrate its five fundamental principles: Sort, Set in Order, Shine, Standardize, and Sustain. It is designed to optimize organization and efficiency of the work environment by ensuring each tool is in the right place, easy to find, and well-identified at any time.

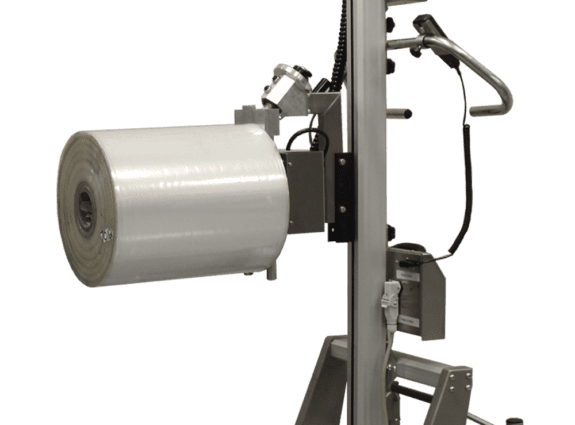

Our mobile roll handling equipment solutions can lift and manipulate any size rolls, light and heavy. Common applications involve moving, lifting, inverting, and rotating. We can lift and rotate rolls, spools, reels, as well as other products of similar size and shape. We also accommodate roll handling requirements that must be transferred to and from pallets which commonly requires rotation between core vertical and core horizontal positions. Contact us now to get a free customized quote.

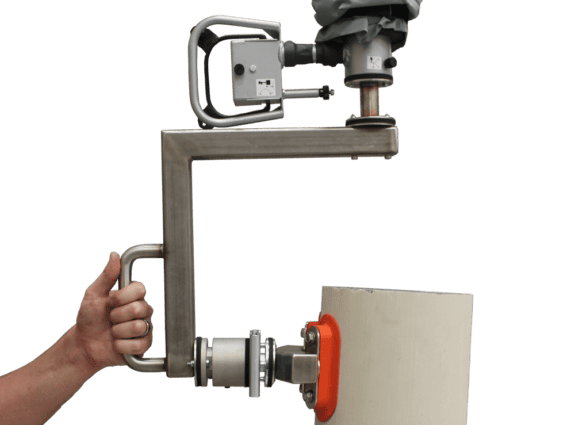

If you need to transport or manipulate heavy drums or containers in your facility, our drum handling solutions are perfect for the job. We handle drums of various types and materials, ranging from fiber to metal to plastic. We also offer various accessories such as pour chutes and retainers. We grip the drums by squeezing them from the outside using R-on-I’s Squeeze-O-Turn™ technology. This allows up to safely and securely rotate drums to pour contents or just pick and place them. We have used vacuum suction in some applications as well if more grip is needed. Get started today by contacting us below.

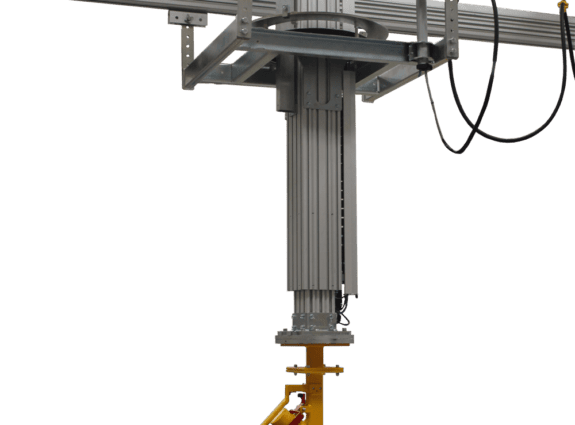

Automation is necessary to bring the part cost down for American products to be competitive with the rest of the world. In pursuit of this goal, we provide our clients with plenty of robotic and non-robotic assembly applications to ultimately save time, space, and labor. Our ergonomic industrial assembly products include the highest quality conveyors, pick systems, robots, wrappers, lift & tilt units, and many more. Contact us today for a full line card of the manufacturers we work with.

Work is not always confined to a single workstation and tools must be moved around accordingly. Our flexible, lightweight trolleys are ideal for this situation, significantly increasing productivity by up to 30%.

Because each task is different and requires dedicated tools, our products adapt seamlessly to changing tasks and layouts. Trolleys are easy to design and suit a multitude of uses thanks to their modularity and versatile accessory components. Our cart and trolley applications are built to ease the manual handling of loads (also known as manual materials handling or MMH). Reduce the risk of lower back injuries, low back pain, and occupational fatigue with our ergo industrial solutions focused on worker health and safety.

Work is not always confined to a single workstation and tools must be moved around accordingly. Our flexible, lightweight trolleys are ideal for this situation, significantly increasing productivity by up to 30%.

Because each task is different and requires dedicated tools, our products adapt seamlessly to changing tasks and layouts. Trolleys are easy to

design and suit a multitude of uses thanks to their modularity and versatile accessory components. Our cart and trolley applications are built to ease the manual handling of loads (also known as manual materials handling or MMH). Reduce the risk of lower back injuries, low back pain, and occupational fatigue with our ergo industrial solutions focused on worker health and safety.